Portfolio Details

Project Information

- Category: Biofabrication devices

- Client: SabioTek

- Project date: jan, 2025

Project Overview

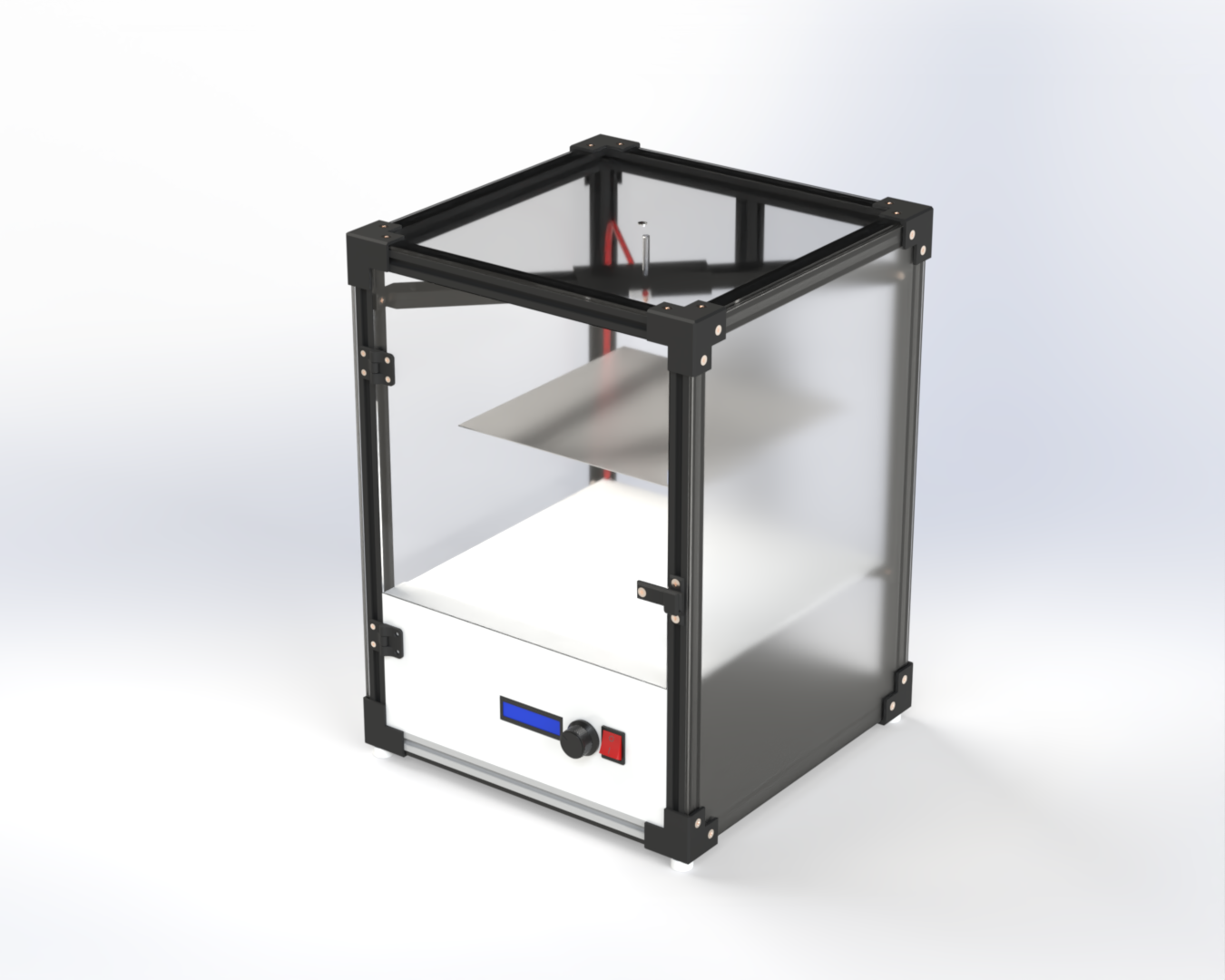

This project involved the design and fabrication of a hybrid electrospinning and electrospraying system for advanced material and biomaterial research. The device enables precise control over fiber morphology and particle generation by integrating high-voltage power delivery, programmable syringe extrusion, and collector stage motion control into a single, compact unit.

Developed from scratch using aluminum extrusion framing, custom 3D-printed mounts, and a modular electronics setup, the system supports interchangeable syringe heads and configurable spinneret collector distances. It provides stable electrostatic fields up to 30 kV, allowing both polymer fiber formation and nanoparticle deposition under controlled environmental conditions.

Key Features

High-voltage control

Adjustable within range up to 30 kV with safety interlocks.

Adjustable collector stage

Variable distance (0–35 cm) and motion control for uniform deposition.

Environmental chamber

Fully enclosed using acrylic panels to allow deposition of materials contains solvents and to avoide electric shocks